Service 1 OilPure Fluid Care OPFC – English

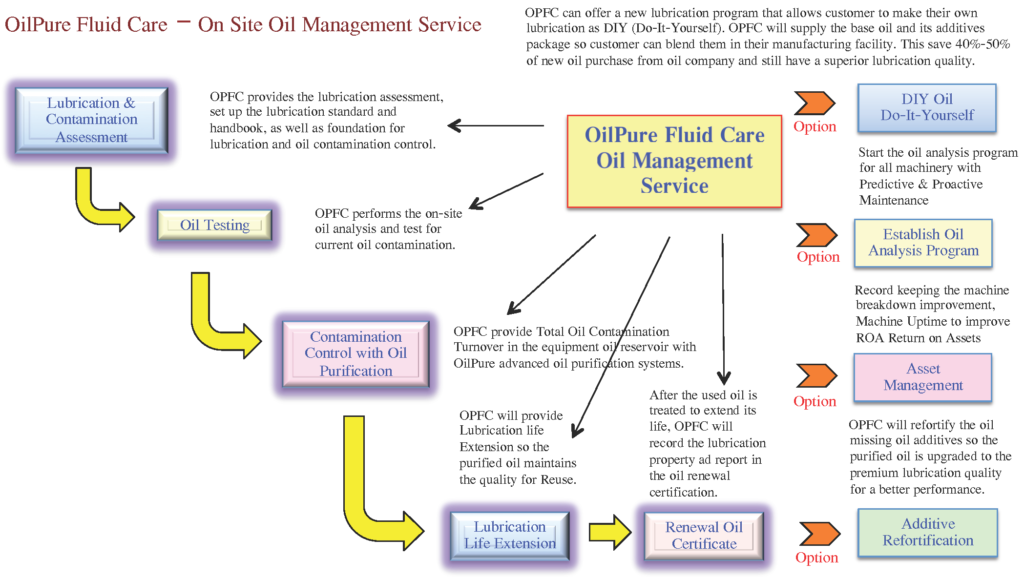

On-Site OilPure Fluid Care (OPFC) Service

- Lubrication & Contamination Assessment

- OPFC provides the lubrication assessment, set up the lubrication standard and handbook, as well as foundation for lubrication and oil contamination control.

- Oill Testing

- OPFC performs the on-site oil analysis and test for current oil contamination.

- Contamination Control with Oil Purification

- OPFC provide Total Oil Contamination Turnover in the equipment oil reservoir with OilPure advanced oil purification systems.

- Lubrication Life Extension for Reuse

- OPFC will provide Lubrication life Extension so the purified oil maintains the quality for Reuse.

- Renewal Oil Certification

- After the used oil is treated to extend its life, OPFC will record the lubrication property and report in the oil renewal certification.

- Additive Refortification

- OPFC will refortify the oil missing oil additives so the purified oil is upgraded to the premium lubrication quality for a better performance.

- Asset Management

- Record keeping the machine breakdown improvement, Machine Uptime to improve ROA Return on Assets.

- Establish Oil Analysis Program

- Start the oil analysis program for all machinery with Predictive & Proactive Maintenance.

- DIY (Do-It-Yourself) Low Cost Premium Grade Lubricants

- OPFC can offer a new lubrication program that allows customer to make their own lubrication as DIY (Do-It-Yourself).

- OPFC will supply the base oil and its additives package so customer can blend them in their manufacturing facility. This save 40%-50% of new oil purchase from oil company and still have a superior lubrication quality.

- Oill Testing

- On-site Lubrication Audit will inspect the current quality of lubrication before cleaning by suing the Portable Oil Testing Equipment from OilPure. This oil information include the type of oil, oil consumption, how long the oil has been in service, and type of equipment machinery. This will also include how to collect the used oil for storage.

- Lubrication & Contamination Assessment OPFC visits the plant to get the oil, equipment and economic data

- Lubrication & Equipment Audit to discover economic loss of oil and equipment and process. This will improve the business breakeven and discover the loss that increases manufacturing costs.

- Search for Oil type, oil consumption, annual oil purchase, leaked oil volume, top up oil volume, used oil collection & recovery, and waste oil disposal information.

- Search for Leaked oil information, how to recover leaked oil for reuse and how to control oil replacement and leaked oil.

- Search for Equipment type, quantity of machines, each oil reservoir size, type of repair and breakdown, and equipment maintenance history.

- Search for Downtime information in type of downtime, cost of downtime, number of downtime and cost consequence related to downtime.

- Search for Defect, type of defect, quantity per month, causes of defect and damages.

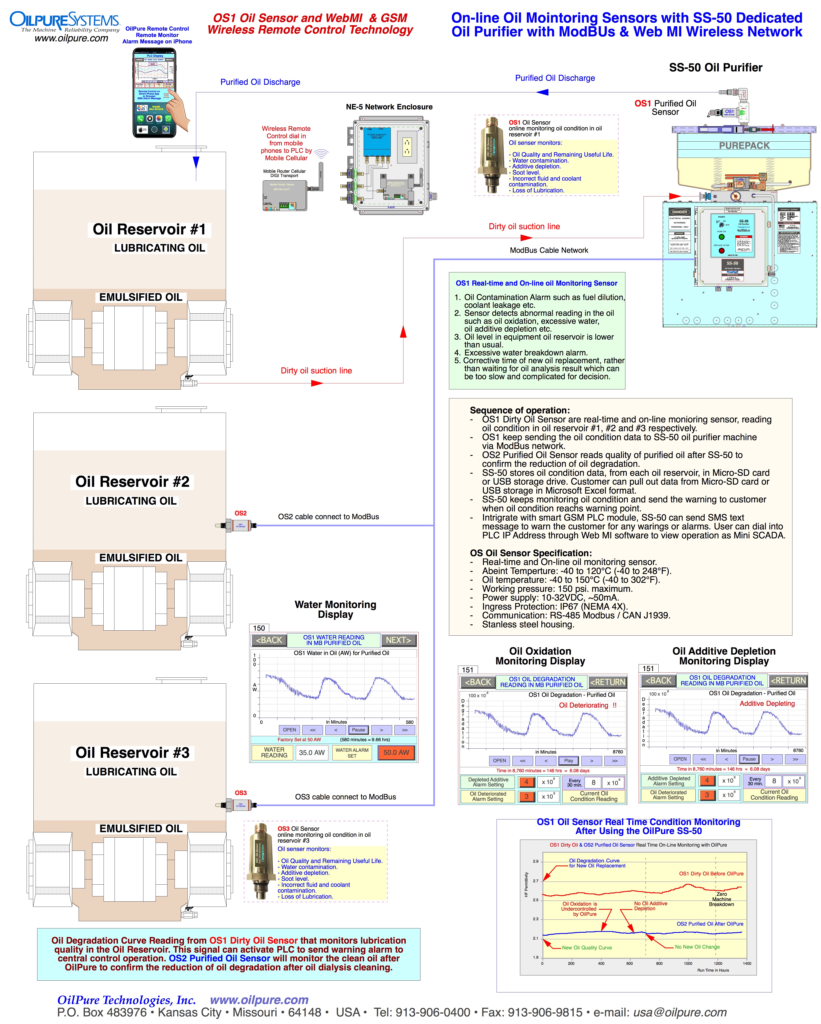

- On-Site Oil Testing & Oil Monitoring Systems OilPure Staff will search for proper oil sampling from equipment or oil storage. On-Site oil testing is performed to evaluation type of oil contamination for the Real Time within an hour.

- Oil samples from equipment in order to establish the Fluid Master Plan Objective to solve the oil problems as well as how to monitor oil contamination in the process.

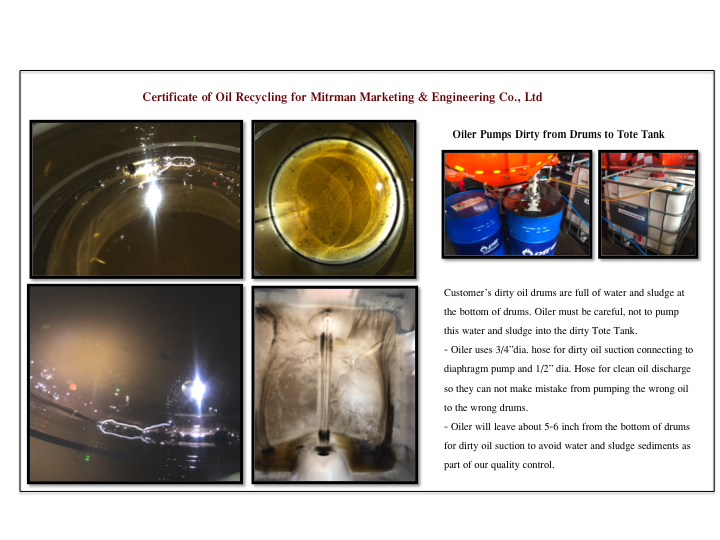

- Leak oil recovered in 200 liter drum or 1,000 liter Tote tank.

- Analyze the test result from oil sampling and lead to solution to problems. Then, select the proper oil purifiers to treat the contamination.

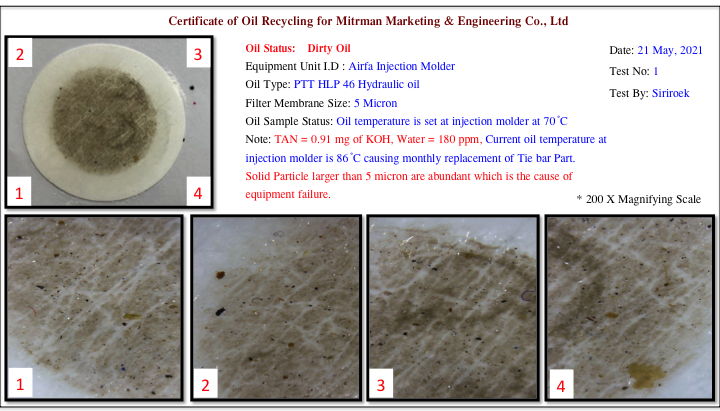

- Oil test report reveals equipment damages causing from the following contamination:

- Particle Count in ISO Code Cleanliness หรือ NAS หรือ DOT Test (Gravimetric)

- Two type of Water – Dissolved Water and Free Water

- TAN Total Acid Number Oil acidity causes the chemical changes in oil lubricity.

- Oil Oxidation Curve reads from OS1 Oil Sensor as compared to new oil curve.

- Oil Additive Depletion remaining the Antiwear additive, Extreme Pressure additive

- Contamination Control OilPure staff will select proper oil purifier equipment to decontaminate the used oil based on the test results.

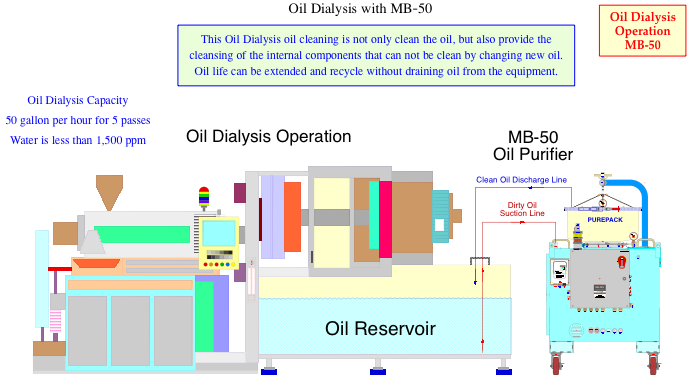

- Oil Dialysis is the continuous oil cleaning by oil purifier while the equipment is still running. Dirty oil is draws from the equipment oil reservoir to oil purifier for cleaning. And the purified oil is discharged back to top of oil reservoir. The Oil Dialysis or Continuous oil cleaning is not only clean the oil, but also clean up the inside of the equipment which can not be done by changing new oil. There is no to drain used oil out of the equipment oil reservoir.

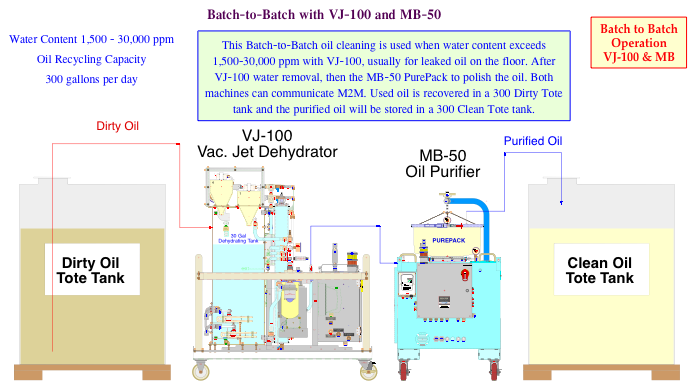

- Batch-to-Batch Oil Recycling is cleaning the used oil collecting from dirty oil storage tank or drums. Used oil is drawn to oil purifier and the purified oil is discharging to a new oil storage tank or drums for reuse.

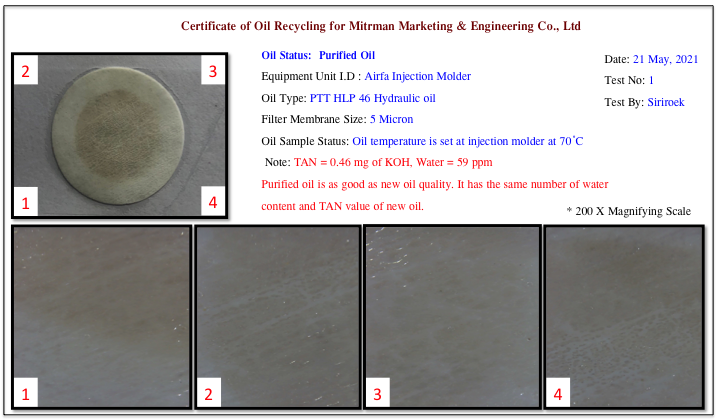

- Total Oil Contamination will be removed from dirty oil and the purified oil will be as good or better than new oil.

- Solid Particle can be reduced between ISO Code 15/13/10 to 17/15/12 or NAS 3-5 Class or Dot Paper Test (Gravimetric) at 0.8 micron cleanliness level.

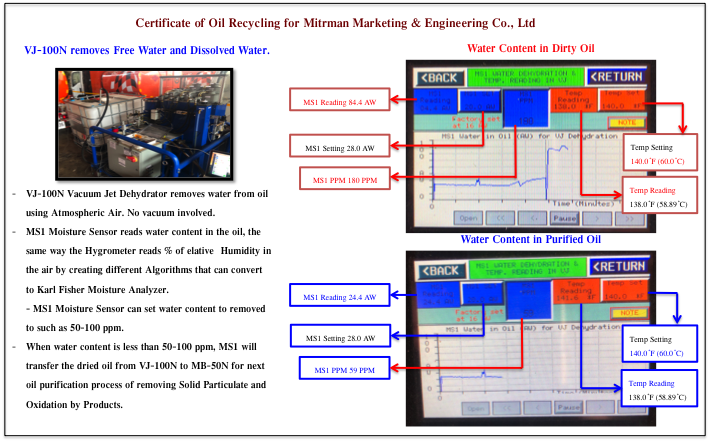

- Dissolved Water can be reduced to 50 -100 ppm

- TAN Total Acid Number can be reduced to 10%-25% closed to new oil TAN value.

- Lubrication Life Extension for Reuse Used oil from equipment oil reservoir or Used oil storage tank can be clean and recycle for reuse so that the purified oil is as good as new oil as described following:

- Oil contamination causes Physical Changes in the oil came from Solid Particle and Water. The Oil contamination causes Chemical Changes came from Oil Oxidation. These Oil Contamination are the sources that derails the lubricity and loss lubrication property.

- In Tribology when Oil Contamination is removed from lubrication, the oil lubricity will come back to the original as oil molecule never breakdown as it was in the ground for several million years.

- Because the Oil Molecule never Breakdown as it used to be Hydrocarbon buried underground more than 10 million years The Fossil structure has been broken down into crude oil Hydrocarbon that can not deteriorate any further. Therefore, lubrication without oil contamination and adequate oil additives can remain in service as long as the oil is free of contamination.

- Oil Additives can be refortified and added back to lubrication to enhance the lubricating properties. Such as Anti Oxidant additive to increase oil temperature withholding from 80 °C to 90 °C. OilPure has the blending technology, oil additives and additive suppliers directly from USA.

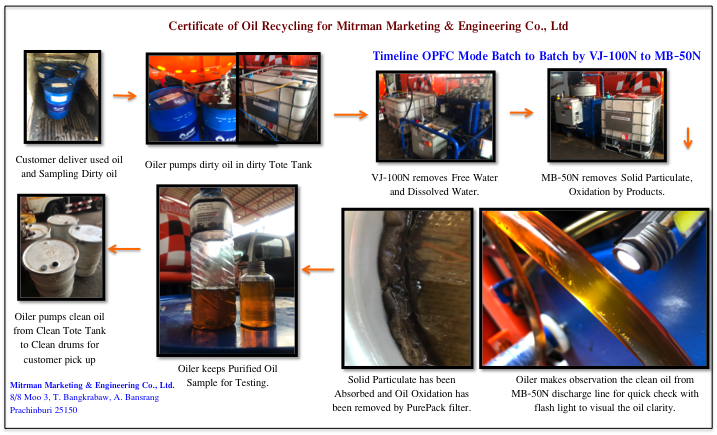

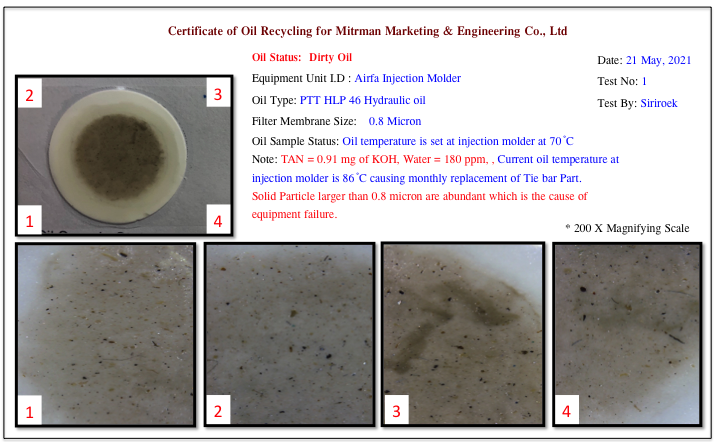

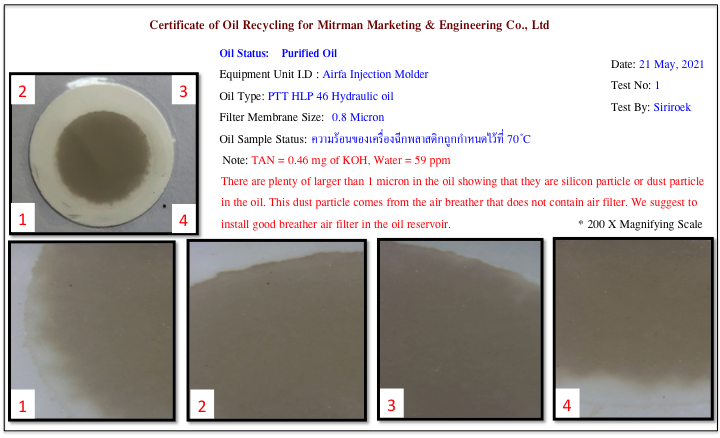

- Oil Management Report & Certification After OilPure Fluid Care service is completed, OilPure will provide the following certificate and documents:

- Certificate of Oil Recycling to comply with the ISO 9000 Quality Control Audit.

- Certificate of Oil Recycling document shows the quality purified oil is met the oil cleanliness standard or as good as new oil.

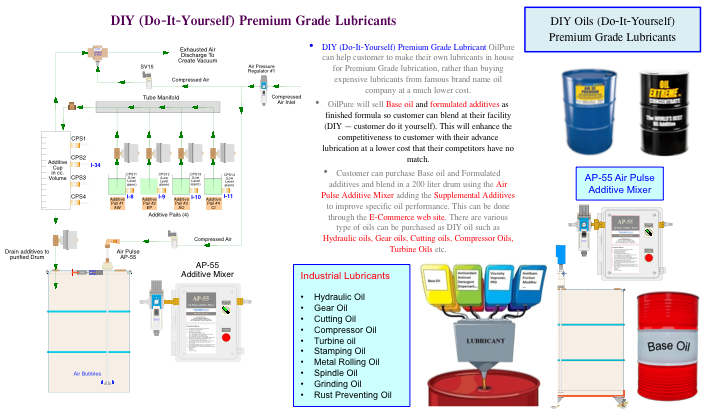

- DIY (Do-It-Yourself) Premium Grade Lubricant OilPure can provide the Do-It Yourself so customer can make their own lubricants in the plant site. This DIY can be a premium grade lubricant with a lot less cost than other brand name oil supplies.

- OilPure will sell the Base oil and its Additives which has already formulated so customer can blend them as needed. This DIY concept comes from America so customer can develop their specialty lubricants in house.

- Customer can buy the Base oil its Additives with formula and simply mix the additives in the 200 liter base oil drum with OilPure Air Pulse Additive Mixer in addition to the Supplemental Additives that can be added for special lubrication properties. This ordering process is done through the E-Commerce web site. Customer can choose proper base oil for different grade different type per their usage such as Hydraulic oils, Gear oils, Cutting oils, Compressor Oils, Turbine Oils and etc.

- Additive Refortification OilPure can suggest user to blend special oil additive in order to make Premium Grade lubricant In House that is superior to the good brand name of oil suppliers with a lot less cost.

- Asset Mangement OilPure can consult how to collect the equipment data such as OEE (Overall Equipment Efficiency), MTBF (Mean Time Between Failure) so these data will help measure and improve machinery efficiency that will enhance ROA Return on Asset.

Example of Oil Certificate of Oil Recycling Report to verify that quality recycled oil is clean as good as new oil.

- DIY (Do-It-Yourself) Premium Grade Lubricant OilPure can provide the Do-It Yourself so customer can make their own lubricants in the plant site. This DIY can be a premium grade lubricant with a lot less cost than other brand name oil supplies.

- OilPure will sell the Base oil and its Additives which has already formulated so customer can blend them as needed. This DIY concept comes from America so customer can develop their specialty lubricants in house.

- Customer can buy the Base oil its Additives with formula and simply mix the additives in the 200 liter base oil drum with OilPure Air Pulse Additive Mixer in addition to the Supplemental Additives that can be added for special lubrication properties. This ordering process is done through the E-Commerce web site. Customer can choose proper base oil for different grade different type per their usage such as Hydraulic oils, Gear oils, Cutting oils, Compressor Oils, Turbine Oils and etc.

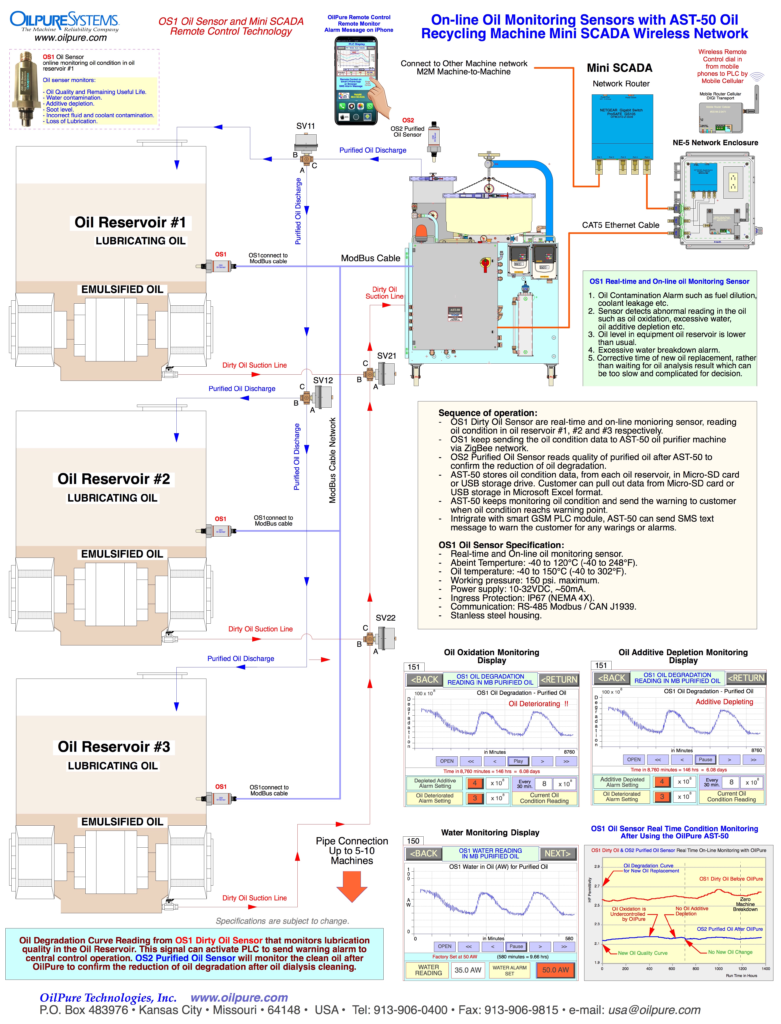

Tribology 4.0 – On-line Oil Monitoring Sensors and Oil Recycling Machine

- Currently we are heading to Tribology 4.0 which the oil contamination control, oil oxidation level and oil additive depletion rate utilizes the Wireless SCADA with Centralized Control System to manage and monitor the changes of these variables. The study of these data changes allow us to better understand the Characteristic and Behavior of the Input Variances that lead us to the machine failures.

- Data collecting is gathered in Data Logging format which yields into Big Data. Using Data Analytics to develop the line of defense in Interactive Proactive that is responsive to problematic occurrence autonomously. This new approach will become a systemic automated operation that will by-pass human error in the process.

- It is the fact that human operator causes most maintenance and lubrication problems in the plant. This human factor must be avoided in such a way to improve efficiency and productivity. This autonomous system is described in the next slides of how the Tribology 4.0 should work for today industries.

© Copyright, August , 2021

Document and information in this website is a proprietary information belonging to OilPure and is not allowed to reveal to public without OilPure consent.