Service 4 Oil Additive Refortification – English

What is Lubrication?

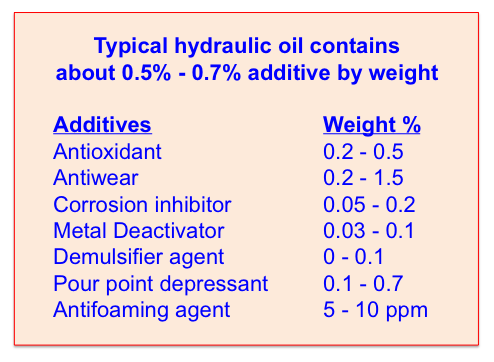

Oil Additives is made of Petroleum Chemicals or Oleic Chemicals fabricating from Fatty Acid in vegetable oil and P Products. Base oil alone is not good for lubrication. Without oil additives base oil is no use for lubrication.

Oxidation-By-Products

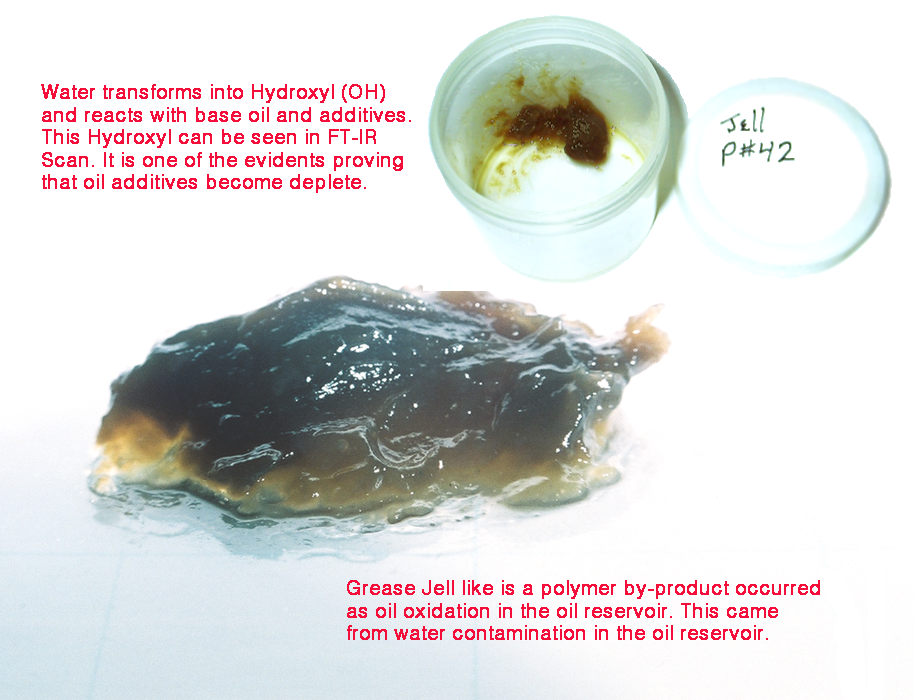

- Oxidation-By-Products mostly comes from the depleted breakdown of oil additives. Actually they become bad additives after breaking down. ZDTP Zinc Dithiophosphate or Zinc additive is oxidized through heat and become Zinc Oxides or Varnish or Oxidation by Product in hydraulic oil.

- Varnish or Oil Oxidation By Product comes from various different forms and sources. Most of them come from the Breakdown of Oil Additives such as Zinc Oxides or Phosphorus Oxides which is similar to Salt or Oxides that came from TBN Additive. This derives from Carboxylic Acid of Hydrocarbon Base Oil and cluster into the Oxidation By-Products.

- Concurring Oil Oxidation or Auto Oxidation is a hidden Oil Oxidation by product that most user was not aware of how it happens in the oil as it does not came from Bad Oil Additives. This Concurring Oil Oxidation comes the built up of Electrostatic Charge from Oil Friction flowing through the Pleated paper Filter Media. This type of low micron paper filter is made of Polyester or Rayon Plastic Materials. The Oil Friction generates Electrostatic Charge and Electrify the Oil. Deprotonation Reaction with Hydrocarbon Base Oil generates Carboxylic Acid (R-COOH) and Carboxylate Anion that increases TAN Total Acid Number in the oil, thus promoting Internal Corrosion. This is one of the unsolved problem of Non Zinc lubricating oil that Varnish was found with no source of Zinc Oxides from oil additives.

- Anti Oxidant Additive helps control Free Radicals not to easily interact with Oxygen (Catalyst) from the air and Dissolved Oxygen in the oil to become Peroxides and Oxides. These Oxides or Varnish are typical Oxidation By Products in the oil.

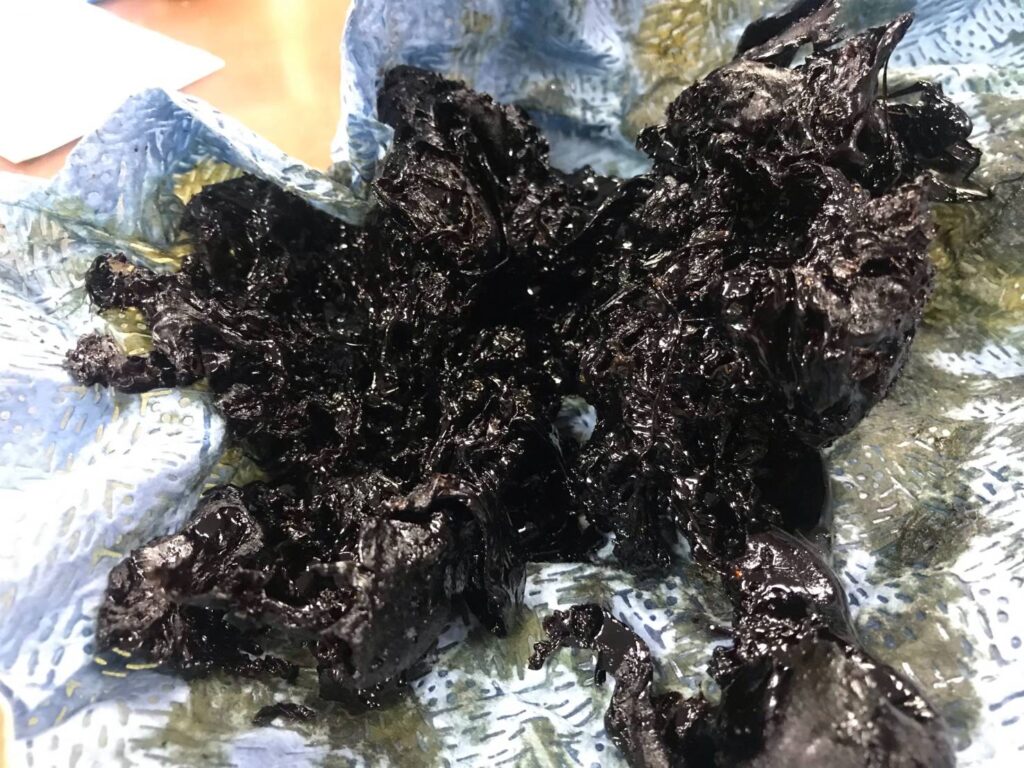

- Peroxides and Oxides is Oxidation By Products in the oil will generate Polymers or Corrosive materials in the Oil:

- Polymers (Long chain hydrocarbon)

- Acids

- Aldehydes

- Alcohols

- Ketones

In general there are two type of Oil Oxidation:

- High Thermal Oxidation looks like hard brownish color, dried chocolate like sticking on part surface. They are very hard material but very Brittle.

- Low Thermal Oil Oxidation looks like Greasy soft material stick on part surface.

Hydrocarbon Oxidation Mechanism:

- Initiation

- R-H + O2 (Oxygen) —–> R° + HOO (Water) ……… with Heat

- ROOH (Peroxide) —–> RO° + OH° (Hydroxyl)

- Propagation R° + O2 —–> RO2°

- RO° + O2 —–> RO2°

- RO2 + RH —–> RO2H + R°

- HO° + RH —–> R° + H2O

- Termination

- 2RO2° —–> Non Radical Products

- R° + ROO° —–> ROOR (Peroxide)

- R + R° —–> R-R

- Summary of Oxidation Control

- RO2° = Additive Molecular Chain Breaking

- Hindered Phenolic

- Aromatic Amines

- ZDTP

- Copper Salts

- RO2H (Peroxide) = Peroxide Decomposition

- ZDTP

- Sulfur Components (Base Oil)

- RO2° = Additive Molecular Chain Breaking

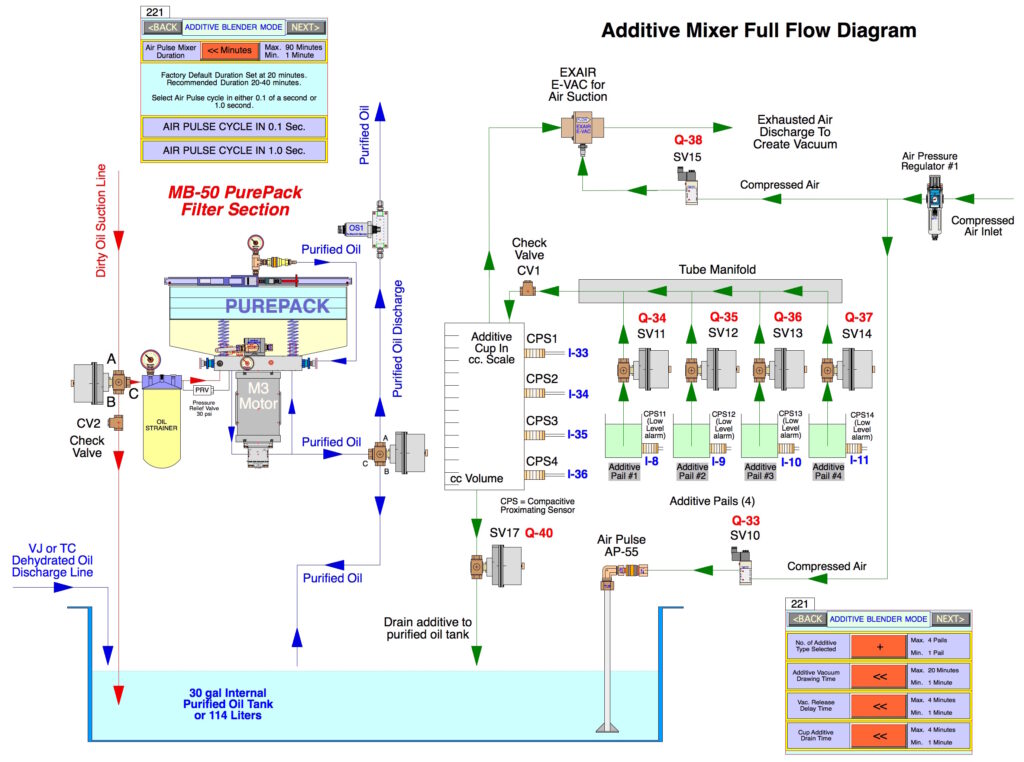

- Oil Additives can be prescribed and refortify to the used clean lubricants. However, this used lubricants must be clean and free of Solid Particle, Water and Oil Acidity or Oxidation. This process is called “Supplement Additive Refortification (SAR)” to enhance oil quality on existing used lubricants.

- If used lubricant is not clean. adding oil additives will cause the Backfire creating more rapid Oil Oxidation. The adding additives will turn into bad additives very soon.

Supplemental Additive Refortification (SAR)

- Supplemental Oil Additives can be refortified only when used oil is clean and free of all oil contamination.

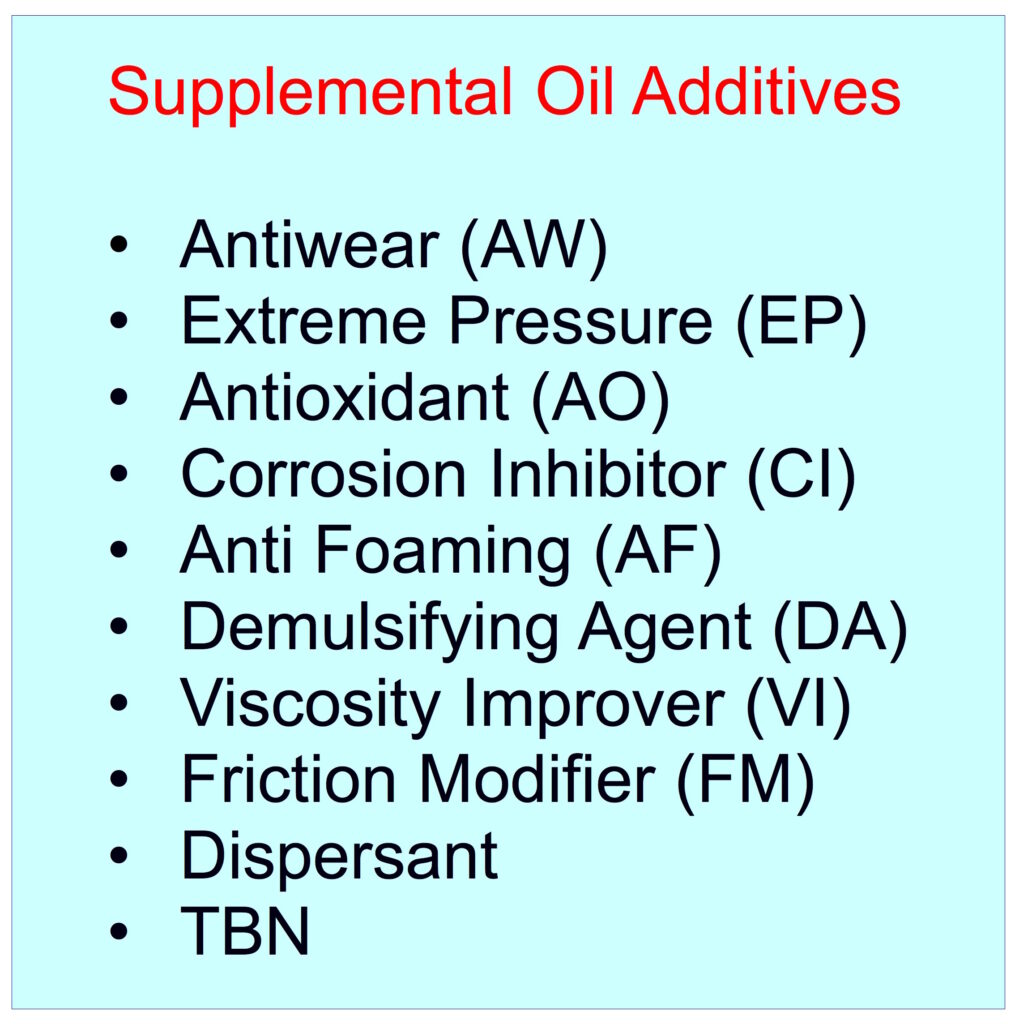

- These Supplemental Oil Additives will help existing lubricant to carry more loads, operate in higher oil temperature than normal as well as water resistant that repels water from being Emulsion in the oil. All brand name lubricant additives are formulated in Mass Market as One Type Fit All and never be able to customized to specific need of machinery. OilPure can help customizing this special application for customer which oil companies will not do so.

- OilPure is capable of counseling how to prescribe Supplemental Oil Additives to enhance lubrication performance for better equipment protection than those of new oil performance. Due to fierce competition from oil companies everyone tries to reduce cost by put minimal amount of additives in their new oil. This makes new oil downgrade and have inadequate performance at the the beginning.

- OilPure has plenty sources of additive suppliers in America and can directly import to customer with no middleman in between to save costs to customer.

- In Thailand Additives Importer will not sell additives to end user for small quantity (in 200 liter drum). A minimum order will be a truck load or train load of 5,000-10,000 liters per order. They will not sell individual performance additives so call “Component“. They can sell only “Formulated” additive package which is a finish product which end user would have no idea what are these additives.

- 80% of equipment failure comes from Oil Contamination as a Root Cause which can be easily prevented by OilPure. The other 20% of equipment performance can be improved from Supplemental Additive Refortification (SAR).

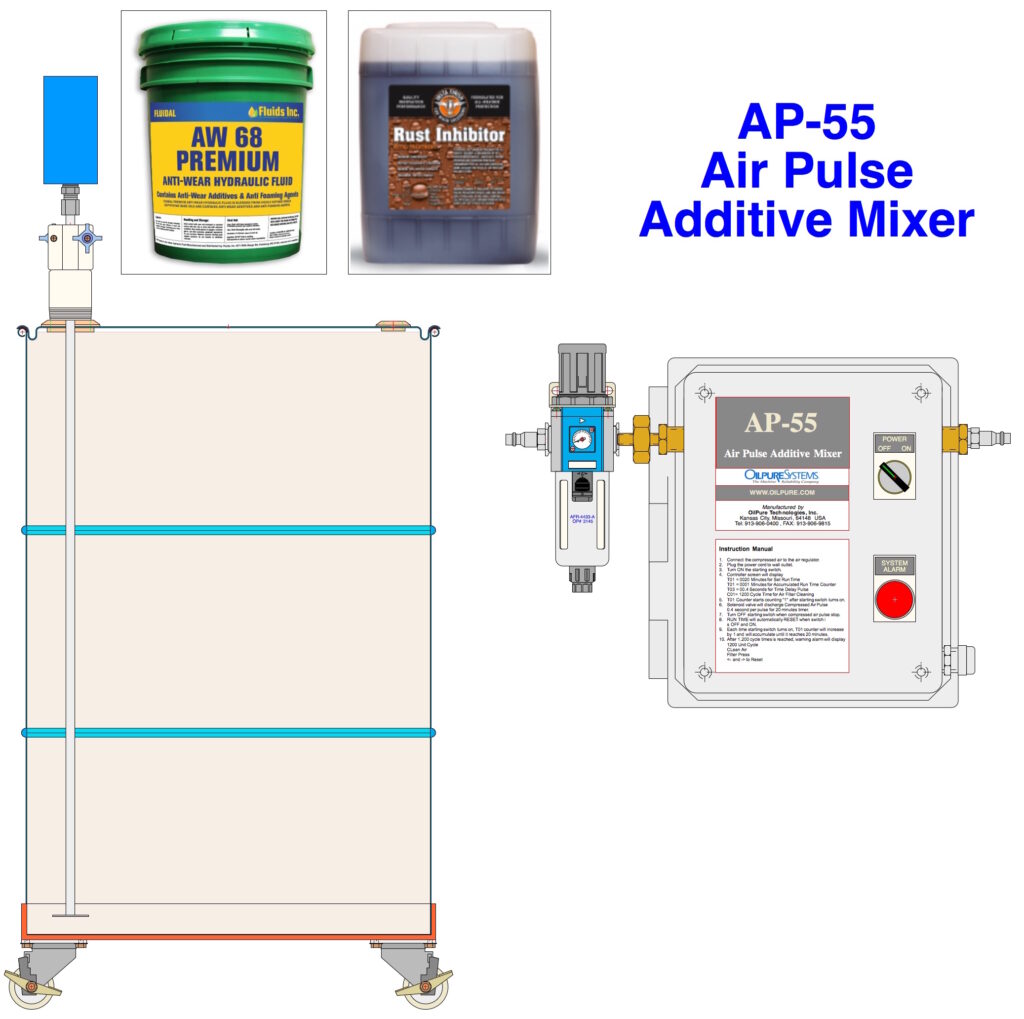

OilPure Equipment has a built-in Additive Mixer unit so Supplemental Additives can be added after oil is purified by OilPure equipment.

AP-55 is an OilPure Additive Mixer to mix additives with base oil using air as mixing medium.

Type of Supplemental Oil Additives

© Copyright, August , 2021

Document and information in this website is a proprietary information belonging to OilPure and is not allowed to reveal to public without OilPure consent.